Boat Plans Nz

The engine room received one more coating of paint on the hull and sole framing last weekend in preparation for starting the sound proofing. Well, I hope its sound proofing, as it will be a real pain in the ass to re do this once the boat is launched.

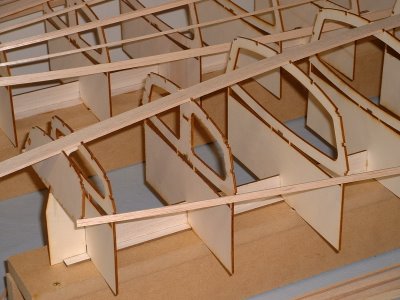

My system for sound proofing is pretty basic. I foamed the metal ( see the last post), and now Im attaching a 1" thick mineral wool board the the framing. Over this mineral wool Ill attach a perforated aluminum sheet as my finished wall material.

As best as Ive learned, the idea behind sound dampening is to decouple the structure from the sound. Sound travels in waves and the idea behind getting rid of it is to try to absorb it. My system is to provide a barrier between the living spaces and the engine room noise. My thoughts are that the sound will pass through the perforated aluminum then be absorbed by the mineral wool board and also by the foam underneath.

The mineral wool Im getting is discarded seconds that came out of a large sheet metal fabrication shop. Id love to have 3 x 5 boards, but Im only able to get 2x4 boards ( the price is right though). Because Im not able to pick my size, Im having to adjust my framing. In the areas I know Im going to have to attache lots of conduits, or other mechanical items, Im first installing plywood before installing the rock wool board. With the plywood on the hull frami

ng ( 1/2" ply ), I dont have to worry about the rock wool laying out to hit the framing so there is almost no waste of the rock wool. I also have unlimited points of attachment for my future mechanical installations. For the ceiling though, Im going to have to add a firing strip so the rock wool waste is minimized while I keep an eye on the weight Im adding.

Ive got a little of the product up and on the walls and part of the ceiling. Im working in the corner where the generator will be installed, and Im amazed at how well the sound seems to be vanishing from just having that small area installed. Its no longer necessary to wear ear plugs while working in the hull. The only drawback is that the engine room is starting to get hot from the heat from the lights.

The perforated aluminum looks fantastic and gives me just the gear head look I want for my engine room. Once the material is screwed to the wall, it stiffens up nicely. You have to look closely to see the rock wool underneath, so I feel good about the ability of the perforations to contain the rock wool while also letting the sound waves into the dampening zone. The open area of the perforated sheathing is 34%. I picked up some advice from the good posters at Metalboatbuilding.org on how the cut the stuff. Its so nice to be able to start seeing some finishing material finally going on.

Because the rock wool is 1" thick Im going to have to fabricate some corner pieces or trim some areas out with aluminum angle. One of these areas is by the doors as you can see from this picture. Im lea

ning towards angle in some areas, while in other areas, Im going to try to brake ( bend a corner) the material in to an outside or inside corner.

I took a crack at bending some material into a corner, and it worked out OK. Having corner pieces makes the job look much more finished and I dont have to be as part

icular on the fit.

I had to add firing strips to the main area of the engine room ceiling. While I hate to loose another 3/4" of head room, Im willing to take the trade as this allows my rock wool to go up with less waste. The frames for the boat are 30" on center, and my rock wool sheets are 24" x 48". I dont have the choice of 3 x 5 sheets so I added the firing strip to make things work better and get the most bang for my buck in regard to how much rock wool I have to buy.

I started out cutting the perforated aluminum with snips, but Ive now switched over to my table saw. I added a board to the saws fence so the 16 gauge material will not slide under the fence. The table saw does an excellent job of cutting the material and it looks like it was done on a shear.

You might have noticed I have some plywood installed under the rock wool. I have plywood over the fuel tanks to protect the paint job on the tank and also to give me a way to easily attach engine room components to the tanks. I plan for some cabinetry and shelving, among other things, to be installed on top of the tanks. The forward and aft water tight bulkheads also received 1/2" plywood. I installed plywood on the aft bulkhead due to the idea that my generator will sit on the starboard side, and my fuel transfer/polish manifolds and pumps will be on the port side. I dont know the exact layout of any of these components, so I put the plywood up to make it easier to attach the various bits and pieces of each system. I went with plywood on the forward bulkhead as this is the area where my work bench will be, and I want dont want to be limited to the bulkhead framing as the only points of attachment for various things.

I cut it a little close on my measure

ments for my fuel tank fill points. I wanted the fill lines to be as close to the outside hull sides as possible, and as you can see I achieved that. I had to hog out a bit of the rock wool, then push the aluminum in to get the two inch nipple to thread in. The rest of the assembly will fit just fine as the hull is leaning outboard at this area of the boat.

Im pretty happy how the material bends and the fact that Im a

ble to fabricate some of the corner pieces I need. This picture is where the ceiling jumps up to accommodate my door. This detail is the same on both the forward and aft sections of the engine room. This detail also gives me three more inches of headroom over my work bench.

The room is about 70% complete in regard to fitting out the aluminum wall and ceiling sheathing, and 100% finished regarding the sole, so I decide to drop in the generator. The engine room is now completely closed off. Im going to miss that large opening as it was easy to drop material into the space, and it also made things nice in regard to ventilation.

The engine room, for the most part, is sheathed. I still have to cover the seams with some trim, but Ive yet to find a source or figured out what the trim will look like. Im thinking I"ll go with a 1" piece with some sort of slight brake on both edges.

Do you find information about

Boat Plans Nz are you looking for? If not, below may help you find more information about the Boat Plans Nz. Thank you for visiting, have a great day.

ng ( 1/2" ply ), I dont have to worry about the rock wool laying out to hit the framing so there is almost no waste of the rock wool. I also have unlimited points of attachment for my future mechanical installations. For the ceiling though, Im going to have to add a firing strip so the rock wool waste is minimized while I keep an eye on the weight Im adding.

ng ( 1/2" ply ), I dont have to worry about the rock wool laying out to hit the framing so there is almost no waste of the rock wool. I also have unlimited points of attachment for my future mechanical installations. For the ceiling though, Im going to have to add a firing strip so the rock wool waste is minimized while I keep an eye on the weight Im adding.

ning towards angle in some areas, while in other areas, Im going to try to brake ( bend a corner) the material in to an outside or inside corner.

ning towards angle in some areas, while in other areas, Im going to try to brake ( bend a corner) the material in to an outside or inside corner. icular on the fit.

icular on the fit.

ments for my fuel tank fill points. I wanted the fill lines to be as close to the outside hull sides as possible, and as you can see I achieved that. I had to hog out a bit of the rock wool, then push the aluminum in to get the two inch nipple to thread in. The rest of the assembly will fit just fine as the hull is leaning outboard at this area of the boat.

ments for my fuel tank fill points. I wanted the fill lines to be as close to the outside hull sides as possible, and as you can see I achieved that. I had to hog out a bit of the rock wool, then push the aluminum in to get the two inch nipple to thread in. The rest of the assembly will fit just fine as the hull is leaning outboard at this area of the boat. ble to fabricate some of the corner pieces I need. This picture is where the ceiling jumps up to accommodate my door. This detail is the same on both the forward and aft sections of the engine room. This detail also gives me three more inches of headroom over my work bench.

ble to fabricate some of the corner pieces I need. This picture is where the ceiling jumps up to accommodate my door. This detail is the same on both the forward and aft sections of the engine room. This detail also gives me three more inches of headroom over my work bench.