Boat Plans Bruce Roberts

Every morning at 5:30 or so, I step out on to our back porch to do my wood stove duties, and while I can feel the cold, the echo of splitting kindling bouncing back from the frozen trees and earth, really announces the below zero mornings. A long stretch of below zero nights and daytime highs in the single digits, and low teens, has finally given the Ohio river a crust of ice weve not seen since the late 1970s. On these frozen mornings as I gather kindling, I have recently heard a great horned owls deep, hollow calls, and I feel better knowing the earliest mating bird species in North America has begun tending its nest. A cold winter has lost its novelty, and Im ready for spring.

.jpg)

During this type of weather, "for pay" work has come to a standstill, but I continue to make progress on board. This week found me routing the six inch heat duct from the salon in to the wheel house via a galley cabinet, and the wheel house settee. Because Im getting ready to build the wheel house console, I wanted to tidy up some of the elements under the console. I connected the air line manifold under the console so I can hook my air tools to this area vs routing air hose from the lazarette, and also made up the air connection for the air horn. I cleaned up some of the wiring under the console and got it temporarily strapped to the forward bulkhead, and also connected my two 30 amp shore power feeds to the smart plug inlets. I built the wheel house settee, mounted some of the galley cabinets, and all in all had a pretty decent week.

We have a settee in the salon, and now another in the wheel house. Besides having another item checked off of the list, I needed the wheel house settee built in order to verify the final position of the wheel. The final dimensions of the settee are 46" wide x 72" long.

.jpg)

The table will collapse down and make for a full sized berth. There are three drawers under the settee along with the 6" air conditioning duct that feeds the wheel house. I purchased one pedestal for the table, but Im going to have to either add another pedestal, or build some creative folding brackets to support the table when its collapsed for berthing. The settee benches have removable seats for stowing life jackets.

.jpg)

I plan on having cushions made for the seats, but for near future the seats will be hardwood. For the seats, I used 3/4 cherry plywood, and glued on solid stock, rounded over, to finish the edge. The seats look good, and will do just fine until funds for an upholsterer can be found ( way down on the list ).

.jpg)

A strategic cleat and some Velcro hold the seats fast. Ill have to look at head room pretty close, but I think theres room for a small cabinet or shelf above the settee on the bulkhead wall. At least one of the drawers will have to be notched to accept the table pedestal, and two drawers if I add another pedestal.

The layout of the console has the wheel centered on the port side fixed window. To port of the wheel is the navigation desk, to starboard is a fixed cabinet that will hold charts and other stuff. The height of the wheel house console will be 36", and the height of the navigation desk will be 30".

.jpg)

Right now, the wheel is 16" off of forward bulkhead. With the wheel on the port side center window, the navigation desk feels cramped. Im going to move the wheel from its current off center local, to be on the center line of the wheel house. This move will represents the helm pump moving 13" to starboard. Ill be able to leave the welded pedestal in place and will only have to fabricate a bracket to weld to the existing pedestal. If I were to cut, move, and re weld the pedestal, Id be getting in to foam and paint damage to the master cabin ceiling. The distance between the wheel and the settee is 52". Besides moving the helm pump to the center of the wheel house, Im going to push it 2" further away from the bulkhead. The additional 2" will make the console 18" deep, which makes me feel better, and I still will have adequate room between the captains chair and the settee. The navigation desk will be 24" deep along with the cabinet to starboard of the wheel. The console will now be "notched" in to the forward array which makes the captains chair/ work, the desk work, and the space between the back of the chair and settee work. Between I pads, smart phones, and inexpensive chart plotters, I wonder if paper charts are fast becoming a thing of the past. Technically, Im the last year of the baby boomers, and I still write checks and carry cash in my wallet, so Ill carry charts until the winds of change blow in my window. Personally, I like looking at charts and look forward to plotting our way.

Building the galley wall cabinets last summer, I had mocked up the salon ceiling in order to get the angle for the cabinet doors.

.jpg)

I had left plenty of meat on the port side style to fit the cabinet to port side wall along with enough wood on the top rail to scribe the cabinet to the ceiling. The only problem is that the actual ceiling angle changed a little from my mock up to the actual site built ceiling. This slight oversight, while not crazy, had me scribing the top rail of two of the doors to make the wall cabinets look good. I"m not 100% pleased having to have scribed the door rail, but I do like the way the doors look, and especially like how the angled raised panels match the camber of the ceiling. I had to cut about 3/4" from one of the microwave cabinet doors, and the same from the outbound large wall cabinet door.

.jpg)

It seems like every day I show up at the boat, I bring 50 lbs of something on board, so I needed a few cabinets installed to be able to start stowing "stuff". Between the few galley cabinets and the wheel house settee, I now have some decent topside tool stowage that helps me out by not having to run down below to get "stuff".

Im going to continue on with the wheel house, so the next order of business is to get the console to some level of completion. Im not going to be able to button her up as I have to leave room to land wires and run controls.

Cheers

Do you find information about

Boat Plans Bruce Roberts are you looking for? If not, below may help you find more information about the Boat Plans Bruce Roberts. Thank you for visiting, have a great day.

I think Ive taken the salon as far as I can in regards to building cabinets and furniture.

I think Ive taken the salon as far as I can in regards to building cabinets and furniture. The latest project completed was fabricating the end caps for the dinette benches, and a small table that will sit between the two comfy chairs we will have. I think the small table will house the am/fm stereo for the salon, and has a drawer for stashing the remote control for the TV.

The latest project completed was fabricating the end caps for the dinette benches, and a small table that will sit between the two comfy chairs we will have. I think the small table will house the am/fm stereo for the salon, and has a drawer for stashing the remote control for the TV. The end caps for the bench, while not a job, required a bit of time. Because of the 16" width, the end caps needed to be glued up. I had to decide how I wanted to have the bench seat riser connect to the end cap and chose a dado which had to be plowed in to the end cap. I did not want to see end grain wood on the end caps, so I fabricated a cap that had a dado plowed in to it so it could slip over the top of the end cap. While I was building the end caps for the salon dinette, I also did the same thing for the wheel house bench seating.

The end caps for the bench, while not a job, required a bit of time. Because of the 16" width, the end caps needed to be glued up. I had to decide how I wanted to have the bench seat riser connect to the end cap and chose a dado which had to be plowed in to the end cap. I did not want to see end grain wood on the end caps, so I fabricated a cap that had a dado plowed in to it so it could slip over the top of the end cap. While I was building the end caps for the salon dinette, I also did the same thing for the wheel house bench seating. The wheel house floor has a decent camber to it, and also falls off grade forward to aft. I dont think the super structure is going to rack when we lift it, but Im not 100% sure it wont, and theres no point fastening any finish ply to the front of the wheel house if theres a chance it could move.

The wheel house floor has a decent camber to it, and also falls off grade forward to aft. I dont think the super structure is going to rack when we lift it, but Im not 100% sure it wont, and theres no point fastening any finish ply to the front of the wheel house if theres a chance it could move. I did figure out the camber of the wheel house floor, and fabricated the face frame for the bench seat drawer unit. I gave myself plenty of room to scribe the face frame to the floor and still have an inch of face frame left on the bottom once it was fit. Because I not had the face frame built, I had the drawer size in front of me, so I decided to build the three drawers that will go in the assembly. The far port side opening in the face frame is for the air conditioner vent that supplies the wheel house.

I did figure out the camber of the wheel house floor, and fabricated the face frame for the bench seat drawer unit. I gave myself plenty of room to scribe the face frame to the floor and still have an inch of face frame left on the bottom once it was fit. Because I not had the face frame built, I had the drawer size in front of me, so I decided to build the three drawers that will go in the assembly. The far port side opening in the face frame is for the air conditioner vent that supplies the wheel house.

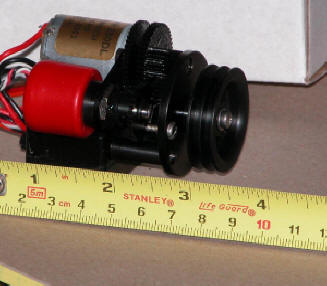

For the last four or five years, Ive been threatening myself to go and buy a real planer to build this boat. The current planer I have is a 15 year old Delta 12" thickness planer that is really undersized for how much lumber Im running through it. I really need a 15", 240 volt machine with a three knife cutter head. The Delta machine has seen better days, but seems to still get the job done. Having sharp knives in the machine is the only way the it has a fighting chance of keeping up with what I ask it to do. When I first bought the machine, I had a local sharpening guy do the knife sharpening work for me. The problem I had with the professional sharpening is that the blades seemed to dull quickly. The edge they produced, while sharp, did not have enough meat on the back side, so the cutting edge would fail, then dull, and begin to leave ridges on the work. As long as the knives do not have a severe nick in them, I prefer to sharpen them myself. To sharpen my jointer and planer knives, I use a jig cut in to a piece of hardwood to hold the knife at the correct angle. The sharpening media I use is 300 grit, 2" wide adhesive sand paper wrapped around a hard wood block.

For the last four or five years, Ive been threatening myself to go and buy a real planer to build this boat. The current planer I have is a 15 year old Delta 12" thickness planer that is really undersized for how much lumber Im running through it. I really need a 15", 240 volt machine with a three knife cutter head. The Delta machine has seen better days, but seems to still get the job done. Having sharp knives in the machine is the only way the it has a fighting chance of keeping up with what I ask it to do. When I first bought the machine, I had a local sharpening guy do the knife sharpening work for me. The problem I had with the professional sharpening is that the blades seemed to dull quickly. The edge they produced, while sharp, did not have enough meat on the back side, so the cutting edge would fail, then dull, and begin to leave ridges on the work. As long as the knives do not have a severe nick in them, I prefer to sharpen them myself. To sharpen my jointer and planer knives, I use a jig cut in to a piece of hardwood to hold the knife at the correct angle. The sharpening media I use is 300 grit, 2" wide adhesive sand paper wrapped around a hard wood block. Before I put the knife in the holding jig, I flatten the back of he knife using the 300 grit block.

Before I put the knife in the holding jig, I flatten the back of he knife using the 300 grit block. With the blades held firmly at the correct angle and the jig clamped in the vise, not much time is needed to revive the edge. Once the edge looks good and all the shiny spots have been taken off of the edge, Ill hone it with the same block using 600 grit self adhesive paper. Sharp tools are one of my pet peeves, and having them makes the work much more enjoyable and consistent.

With the blades held firmly at the correct angle and the jig clamped in the vise, not much time is needed to revive the edge. Once the edge looks good and all the shiny spots have been taken off of the edge, Ill hone it with the same block using 600 grit self adhesive paper. Sharp tools are one of my pet peeves, and having them makes the work much more enjoyable and consistent.

.jpg)

.jpg) The table will collapse down and make for a full sized berth. There are three drawers under the settee along with the 6" air conditioning duct that feeds the wheel house. I purchased one pedestal for the table, but Im going to have to either add another pedestal, or build some creative folding brackets to support the table when its collapsed for berthing. The settee benches have removable seats for stowing life jackets.

The table will collapse down and make for a full sized berth. There are three drawers under the settee along with the 6" air conditioning duct that feeds the wheel house. I purchased one pedestal for the table, but Im going to have to either add another pedestal, or build some creative folding brackets to support the table when its collapsed for berthing. The settee benches have removable seats for stowing life jackets..jpg) I plan on having cushions made for the seats, but for near future the seats will be hardwood. For the seats, I used 3/4 cherry plywood, and glued on solid stock, rounded over, to finish the edge. The seats look good, and will do just fine until funds for an upholsterer can be found ( way down on the list ).

I plan on having cushions made for the seats, but for near future the seats will be hardwood. For the seats, I used 3/4 cherry plywood, and glued on solid stock, rounded over, to finish the edge. The seats look good, and will do just fine until funds for an upholsterer can be found ( way down on the list )..jpg) A strategic cleat and some Velcro hold the seats fast. Ill have to look at head room pretty close, but I think theres room for a small cabinet or shelf above the settee on the bulkhead wall. At least one of the drawers will have to be notched to accept the table pedestal, and two drawers if I add another pedestal.

A strategic cleat and some Velcro hold the seats fast. Ill have to look at head room pretty close, but I think theres room for a small cabinet or shelf above the settee on the bulkhead wall. At least one of the drawers will have to be notched to accept the table pedestal, and two drawers if I add another pedestal. .jpg) Right now, the wheel is 16" off of forward bulkhead. With the wheel on the port side center window, the navigation desk feels cramped. Im going to move the wheel from its current off center local, to be on the center line of the wheel house. This move will represents the helm pump moving 13" to starboard. Ill be able to leave the welded pedestal in place and will only have to fabricate a bracket to weld to the existing pedestal. If I were to cut, move, and re weld the pedestal, Id be getting in to foam and paint damage to the master cabin ceiling. The distance between the wheel and the settee is 52". Besides moving the helm pump to the center of the wheel house, Im going to push it 2" further away from the bulkhead. The additional 2" will make the console 18" deep, which makes me feel better, and I still will have adequate room between the captains chair and the settee. The navigation desk will be 24" deep along with the cabinet to starboard of the wheel. The console will now be "notched" in to the forward array which makes the captains chair/ work, the desk work, and the space between the back of the chair and settee work. Between I pads, smart phones, and inexpensive chart plotters, I wonder if paper charts are fast becoming a thing of the past. Technically, Im the last year of the baby boomers, and I still write checks and carry cash in my wallet, so Ill carry charts until the winds of change blow in my window. Personally, I like looking at charts and look forward to plotting our way.

Right now, the wheel is 16" off of forward bulkhead. With the wheel on the port side center window, the navigation desk feels cramped. Im going to move the wheel from its current off center local, to be on the center line of the wheel house. This move will represents the helm pump moving 13" to starboard. Ill be able to leave the welded pedestal in place and will only have to fabricate a bracket to weld to the existing pedestal. If I were to cut, move, and re weld the pedestal, Id be getting in to foam and paint damage to the master cabin ceiling. The distance between the wheel and the settee is 52". Besides moving the helm pump to the center of the wheel house, Im going to push it 2" further away from the bulkhead. The additional 2" will make the console 18" deep, which makes me feel better, and I still will have adequate room between the captains chair and the settee. The navigation desk will be 24" deep along with the cabinet to starboard of the wheel. The console will now be "notched" in to the forward array which makes the captains chair/ work, the desk work, and the space between the back of the chair and settee work. Between I pads, smart phones, and inexpensive chart plotters, I wonder if paper charts are fast becoming a thing of the past. Technically, Im the last year of the baby boomers, and I still write checks and carry cash in my wallet, so Ill carry charts until the winds of change blow in my window. Personally, I like looking at charts and look forward to plotting our way..jpg) I had left plenty of meat on the port side style to fit the cabinet to port side wall along with enough wood on the top rail to scribe the cabinet to the ceiling. The only problem is that the actual ceiling angle changed a little from my mock up to the actual site built ceiling. This slight oversight, while not crazy, had me scribing the top rail of two of the doors to make the wall cabinets look good. I"m not 100% pleased having to have scribed the door rail, but I do like the way the doors look, and especially like how the angled raised panels match the camber of the ceiling. I had to cut about 3/4" from one of the microwave cabinet doors, and the same from the outbound large wall cabinet door.

I had left plenty of meat on the port side style to fit the cabinet to port side wall along with enough wood on the top rail to scribe the cabinet to the ceiling. The only problem is that the actual ceiling angle changed a little from my mock up to the actual site built ceiling. This slight oversight, while not crazy, had me scribing the top rail of two of the doors to make the wall cabinets look good. I"m not 100% pleased having to have scribed the door rail, but I do like the way the doors look, and especially like how the angled raised panels match the camber of the ceiling. I had to cut about 3/4" from one of the microwave cabinet doors, and the same from the outbound large wall cabinet door. .jpg)

uqcshlukaxroqdfv7926%3Dot)35%3B7%3D626%3D425%3DXROQDF)28598%2B4873259ot1lsi.jpg)