Boat Plans Aluminium Australia

The inside of the super structure was sand blasted, then received two coats of epoxy primer. The roof of the super structure was sand blasted, then received two coats of epoxy primer, followed by 2-4 coats of Acrylic Urethane. The roof of the super structure will eventually get a coat of some sort of non skid coating, but that wont happen until next year. The sides of the super structure is what Im working on now, and is what everyone will see and touch, got sand blasted, followed by two coats of epoxy primer, then three coats of high build epoxy primer. Once Im finished working on the high build, shell get another coat of epoxy primer to seal the high build, then three coats of top coat Acrylic Urethane.

The high build primer is another step I added to only the sides of the super structure. The purpose of the high build is only to help one achieve a nicer finish on the top coat paint. High build primer is able to be built up quickly to a thick layer, then is easily sanded back down. The easiest way to describe it is by calling it liquid body filler.

Just by the nature of the beast, building the super structure created many imperfections in the metal. Every place I welded a frame, or cleat on the inside, a bump in the metal was created on the outside. These small raised areas or "bumps, are called weld print through. If you run your hand over the metal, you feel the bumps. The print through will be extremely obvious on the shiny final coat unless hidden. My method of dealing with it is to hit each spot lightly with the grinder before sand blasting to lower the bump below metal. The high build primer fills the now recessed area, and everything gets sanded smooth. The high build causes the print through to vanish.

All the welds on the super structure were ground flush, and the high build buries all the grinder marks and allows me to sand everything flush. Because the metal has been laying around a long time, some rust developed, and after blasting the rust away, some pitting was evident. The high build fills 99% of those holes.

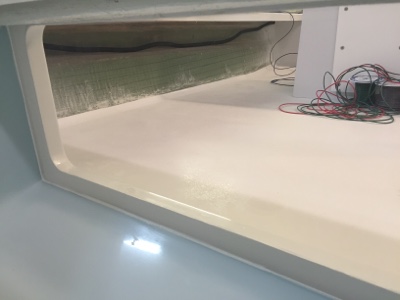

Once the high build primer is sprayed on, I give it at least a day to cure before I start sanding. I use air tools for all my work. My preferred sander is a six inch dual action sander with a hook and loop pad that can accept a shop vac to eliminate the dust. I first sand the panel using 220 grit, and sand any bad spots until I start seeing the under lying epoxy primer. Once I have a panel sanded to 220, I go back over any questionable spots and add a bit of filler, the sand the filler to 220. Once Im happy with how things feel, I sand the whole panel to 400 grit. This sanding process takes some time, but its not hatefull, and goes rather quickly. The super structure is different than the hull in regard to how its built and how it will look, so I dont feel as if I need to long board sand it to make me happy. Once the panel is final sanded, and blown off with compressed air, is is now smooth enough that it begins to show a reflection. I know things are going in the right direction when primer shows a reflection

As one is sanding with the 400 grit pad, the only way one can find imperfections is by feeling them with your hand. Eyes just arent good enough. The surface really is glass smooth, and any bump or ripple is easily felt by touch. The goal for me is to have a respectable looking paint job that will be easy to keep clean. While most areas seem insignificant, those small holes and marks will trap dirt, and ultimately speed up the demise of the paint. Because Im going to be the one whos eyes are going to be looking at things the most, I want it to work for me. As long as the surface is smooth and flat, buffing, polishing and waxing will work well in keeping the paint looking fresh for years to come. This could easily be a 15-20 year paint job.

High build primer is a porous coating and needs to be sealed with epoxy primer before the final coat of Acrylic Urethane is applied. The filler I am using also needs to be sealed, and there are some spots where I sanded to bare metal. There is no way around one more coat of epoxy primer, but thats a good thing and a small price to pay to make sure the job is done right. Once the last coat of epoxy primer is on the boat, I have 72 hours before the primer gets too hard and will not allow the top coat to chemically bond with the primer. If I wait longer than 72 hours, Ill have to scuff to get a less than ideal connection between the top coat and the primer.

Its Sunday morning as I sit and type this entry, and the salon is ready for top coat. I still have to sand the wheel house, but the trim, eyebrow, and all the difficult stuff has already been sanded and faired. The only thing left to be done on the wheel house is the flat panels, and that can be finished in four or five hours. Ill probably seal the super structure with primer early this week, and final coat the super structure by the middle of the week. I have one large area of "orange peel" I need to re paint on the hull, so I plan on sanding and painting this coming Saturday. As long as things go close to my planning, Ill have all the painting COMPLETELY FINISHED by next weekend and Ill be able to unwrap the hull and the super structure.

Cheers,

Do you find information about Boat Plans Aluminium Australia are you looking for? If not, below may help you find more information about the Boat Plans Aluminium Australia. Thank you for visiting, have a great day.

uqcshlukaxroqdfv7926%3Dot)35%3B7%3D626%3D425%3DXROQDF)28598%2B4873259ot1lsi.jpg)